In the ever-evolving landscape of materials engineering, electrically conductive polyimide rods are establishing a notable niche for themselves. https://www.hsjuxin-pi.com/category/products/polyimide-rod/ -performance components are capturing the attention of industries that demand consistency and effectiveness, particularly in contexts where thermal management and conductivity are paramount. As we shift from the developmental stages of development into full-scale production, understanding the advantages and features of electrically conductive polyimide resin rods becomes crucial.

The aerospace industry, renowned for its rigorous standards and difficult environments, can greatly benefit greatly from the application of these innovative materials. Conductive polyimide rods not only meet the stringent requirements for mass and robustness but also perform exceptionally in their ability to withstand high temperatures and oxidative conditions. As designers and designers seek to improve their designs, the adoption of these rods can lead to enhanced efficiency and resilience in aerospace applications, ultimately resulting to more secure and greater efficiency flight systems.

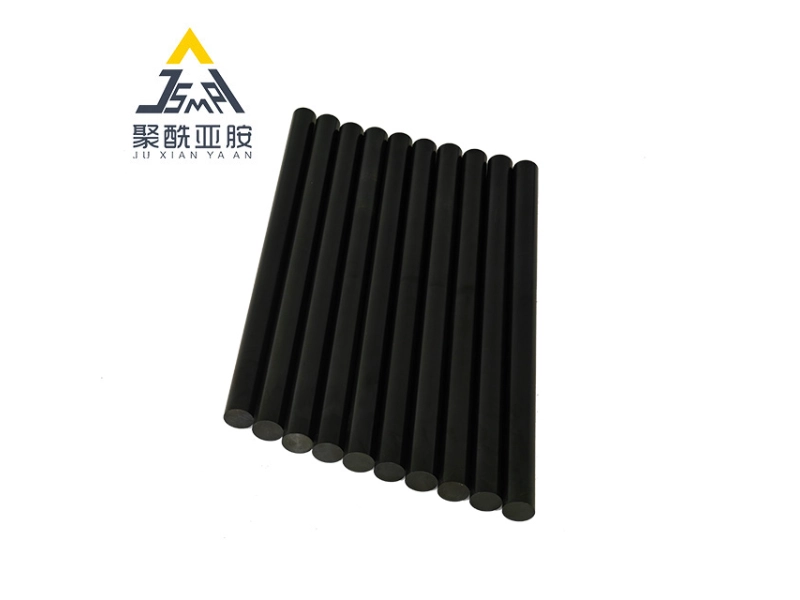

Features of Electrically Conductive Polyimide Rods

Conductive polyimide rods are renowned for their exceptional thermal stability, which makes them suitable for demanding applications, especially in the aerospace industry. These rods can maintain their integrity and performance under extreme temperature fluctuations, ranging from -269 degrees Celsius to over 300 degrees Celsius. This property is essential for components that operate in adverse environments, ensuring dependability and longevity in aerospace applications.

Additionally, notable characteristic of electrically conductive polyimide rods is their excellent electrical conductivity. Unlike conventional polyimides, the addition of conductive fillers enhances their ability to conduct electricity while still retaining the advantages of polyimide resin, such as structural strength and chemical resistance. This dual functionality makes them perfect for use in various electronic components, providing the necessary conductivity without compromising on mechanical integrity.

Additionally, these rods exhibit superb mechanical properties, including high tensile strength and flexibility. This strength allows them to tolerate various stressors encountered during manufacturing and in operational settings. The combination of top-performing attributes ensures that electrically conductive polyimide rods can be molded into complex shapes required in prototypes and final production parts, making them a preferred material in innovative technology development.

Uses in Aerospace Industry

Conductive polyimide rods are growing traction in the aviation industry due to their unique combination of lightweight properties and high thermal stability. These rods are vital components for multiple applications including insulation and electrical interconnections in aircraft platforms. Their ability to withstand extreme temperatures while maintaining performance makes them suitable for critical aerospace components that require consistent operation in harsh environments.

In addition to their physical applications, conductive polyimide rods serve a major role in the evolution of cutting-edge aircraft systems. The space sector highlights the need for materials that not only meet rigorous safety standards but also promote to energy efficiency. With their superior electrical insulation properties and low-weight characteristics, these high-performance polyimide rods are ideal for use in avionics and communication systems, enhancing total system performance while reducing weight.

Furthermore, the inclusion of conductive polyimide rods in aerospace design allows for innovative engineering solutions. Their adaptability enables designers to create more streamlined and productive systems, such as combined sensor packages and multifunctional components. As the aviation industry continues to move towards more sustainable and advanced technologies, the reliance on materials like conductive polyimide rods will undoubtedly increase, laying the way for the future of aircraft design.

From Prototypes through Production

The transition from prototypes into manufacturing through the progression of conductive polyimide rods represents a critical phase that decides the material's performance for actual contexts. During the first model phase, engineers and designers explore the viability of utilizing advanced polyimide rods, testing different compositions and configurations. This exploration enables adjustments in characteristics such as conductivity, flexibility, and heat resistance, guaranteeing that the end product satisfies defined requirements for demanding contexts.

While production processes become refined, the ability to scale emerges as a crucial area of concern. The aerospace industry, notably, demands materials that are able to withstand extreme conditions and maintaining consistent performance. Conductive polyimide rods are adopted in this sector due to their low weight nature and high-quality mechanical properties. The capability to produce these rods in large quantities while maintaining product quality becomes crucial, as even minor inconsistencies in substance functionality might lead to significant issues in aerospace applications.

Once the production process is optimized, the attention transitions to quality assurance and compliance with established guidelines. Conductive polyimide rods need to go through intensive testing to ensure they meet the stringent regulations set forth by aerospace authorities. This includes thermal cycling, mechanical stress testing, and tests for electrical conductivity. Effective validation paves the path for large-scale production, enabling the extensive use of these cutting-edge materials, that not only enhance performance and additionally increase the overall reliability of aerospace systems.

Future Trends in Polyimide

As the need for light materials rises, the future of polyimide seems promising. Innovations in the creation of conductive polyimide rods are expected to enhance their uses across multiple industries, particularly in the aerospace industry. With ongoing studies focused on improving thermal stability and physical characteristics, next-generation polyimide rods may become even more capable in extreme environments, paving the way for their utilization in advanced aerospace parts.

The combination of smart materials and coatings into polyimide technology will also have a vital role in the advancement of these rods. By including sensors or self-healing features, conductive polyimide rods can become versatile, offering not only structural support but also sophisticated monitoring and maintenance features. This movement will be particularly beneficial in the aerospace industry, where security and dependability are of utmost importance.

In addition, the trend toward eco-friendliness in manufacturing will affect the manufacture of polyimide materials. Researchers are investigating bio-based precursors and eco-friendly processing techniques, aiming to lessen the ecological footprint of polyimide synthesis. As the industry shifts towards greener operations, the development of sustainable conductive polyimide rods could lead to wider acceptance and application in multiple sectors, ensuring that these materials remain at the cutting edge of progress.